Academy of High Performance Craft

Our Academy

Crafting your future

Crafting your future

As a specialist in oak frame design, it is important that all our employees are trained to the highest standard. This is why when you embark on a career with us, you will initially join the production team on the shop floor to learn exactly how we do things at Oakwrights.

Working ‘hands-on’, learning the craft will take a minimum of 6 months, but usually takes from 12 months to 2 years. There is a lot to learn and a lot to absorb. If you would like to know more, continue reading below or contact us today.

The 4 areas of ‘hands-on’ learning are outlined below:

The machine shop

The machine shop

These machines take the digital output from the frame department and cut about 80% of the complex joinery used to joint the timber frames. Because this is automation and not man-hours, we have an extremely efficient system in place yet still do not compromise on the intricacy of the jointing, hand finishing all work.

The oak framing shop

The oak framing shop

The output of the machine shop is fed into the oak framing shop, where a team of skilled oak framers do the remaining work to the timbers, this can be adjusting the housings and joints, scribing in the curved members, cutting chamfers, and other hand finished embellishments.

This all culminates in the assembly of the oak frame (the ‘Dry fit’). This is when all the frames, walls, trusses, and roof planes are put together flat to make sure they fit together.

The encapsulation shop

The encapsulation shop

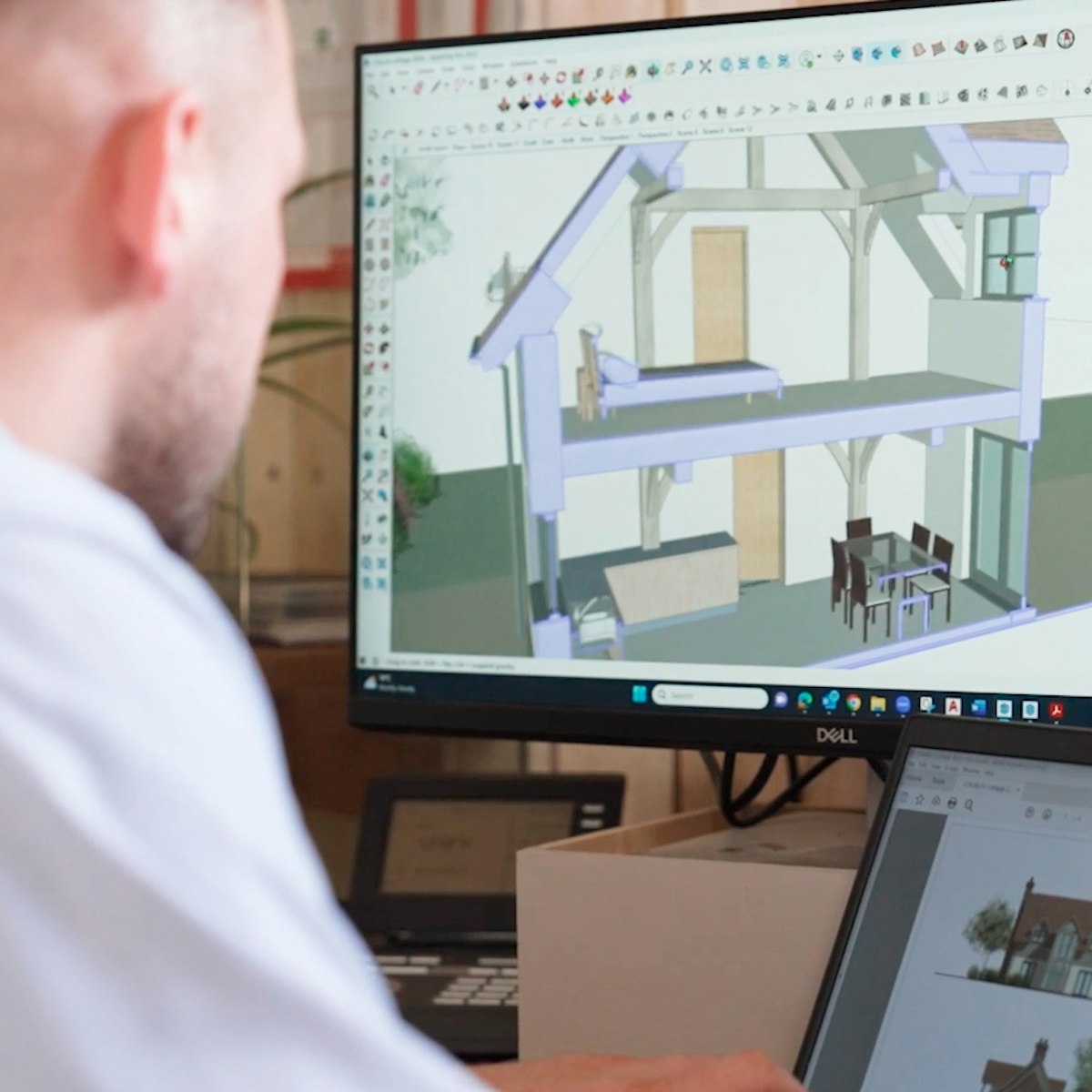

The third production area is the Encapsulation shop. Here we take more digital output from the design department and using another CNC machine we assemble the encapsulation (enclosure) panel systems that wrap around the oak frame.

We have three encapsulation systems including our premier WrightWall Natural system which uses the last of our 3 CNC computer controlled machines to fill the panels with recycled cellulose, as the insulation.

Site crew

Site crew

As you become familiar and competent with the production process you will move to the ‘Make & Take’ phase; this is where you work on a client’s project in production, then join the team who erect the oak frames and panels on site. Our site crew teams travel all over the UK (and all the offshore islands too, Isle of man, Channel Islands etc.) erecting frames and enclosing them.

Progression

Progression

All of the hands-on practical experience will give you a unique insight into how the process works, what it’s like to work for Oakwrights. By using your time at the sharp end to observe all the different roles available in the company (while not being under any pressure) you can decide which area might suit you best – and wait for an opening.

We always like to recruit from inside the company and there are a whole range of roles to which you could progress.

To talk in more detail about any of the above please contact us.

Business as a craft

Business as a craft

We also recognise that Business is also a craft and for this reason we champion employees to undertake a University Diploma programme in leadership and management (which if they hang on for the full 5 years will lead to a Degree in Business Management) The current cohort has been drawn from a diverse cross section of the company, from an Accounting apprentice, site foreman, to various heads of department.

We also send employees on various courses dependent on the requirement of their roles. This includes construction HNCs / HNDs, CPD and accreditation courses for our Architects, Technicians and Structural Engineers which can lead to the opportunity of becoming chartered in their fields.

Apprentice opportunities

Apprentice opportunities

We currently work with several different organisations across the region to employ and develop several apprentices across the company.

With Hereford, Ludlow & North Shropshire College we currently have two team members at different stages of their Wood Product Manufacturing Operative apprenticeships working their way through our three workshops at Sugwas.

With Hereford & Worcester Group Training Association (HWGTA) we have apprentices in both the Finance Team and across the broader organisation with Management Apprenticeships.

With The Development Manager (TDM) over in Worcester we have an IT Apprentice working away and learning the trade to help support all the different teams across the organisation.

We are always interested to hear from young people joining us to further energise the company, from work experience opportunities to internships and apprenticeships. Please do feel free to get in touch to discuss your career aspirations – michaelconnolly@oakwrights.co.uk